Burnaby Waste-to-Energy Facility

The Greater Vancouver Regional District’s (GVRD) Waste-to-Energy Facility (WTEF) was launched in 1988 and since then, it has continually made significant contributions to Vancouver’s management of waste disposal system. The WTEF facility is managed and operated by Montenay, Inc., which makes sure that the disposal of garbage is done in a manner that would not pose hazards to the environment and would be able to produce energy sources that are both valuable and renewable like steam or electricity.

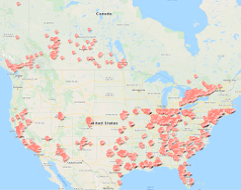

WTEF, the facility in Burnaby, can process some 20 percent of waste coming from Lower Mainland and has contributed well to the region’s administration of waste disposal system. It has so far proven itself to be one of the effectively managed facilities in the continent.

WTEF is situated in South Burnaby, specifically within the commercial and industrial areas. Garbage coming form Lower Mainland, particularly those from New Westminster, North Shore and Burnaby are being processed by WTEF. About 20 percent of the profuse from these named areas are actually processed by WTEF.

Annually, WTEF is able to produce steam at a volume of 900,000 tonnes out of processed waste of some 280,000 tonnes. This is a valuable source of energy that directly benefits the economy and the environment as well. In fact, a good volume of steam is being purchased by a nearby plant that recycles paper and paper products. The use of steam enables the plant to do away with fossil fuels as an energy source. Realizing its potential, the GVRD set-up a turbo generator in the facility in 2003. This generator employs steam to generate electricity that is in turn bought by BC Hydro. By 2006, the team invested $7 million for the upgrade of the facility. After the upgrade, more heat was produced from waste and thus higher levels of electricity were also generated. The cost of operating the waste management facility is covered by the income from the sale of electricity and steam.

Agencies that monitor compliance to environmental regulations declare that WTEF is indeed one of the facilities that maintain a high standard of cleanliness. Moreover, it is recognized by the Solid Waste Association of North America (SWANA) as one of the best established facilities in the continent that operates with the highest standards. GVRD also received the Sustainability Award from the Solid Waste Association of Professional Engineers and Geoscientists of B.C. (AFPGBC) for the success of its turbo generator upgrade program.

In terms of safety and environment friendliness, WTEF employs a waste disposal system that is designed to help maintain a clean and hazard-free environment. Rigid tests on the environment including constant monitoring of emissions reveal that WTEF complies with environmental safety rules and regulations. Tests also showed that the effect of emissions on the quality of surrounding soil, vegetation, and air is negligible.

The plant processes waste via three sections. Each section identically processes waste at approximately 11.5 tonnes per hour. Likewise, each section generates tonnes of steam from waste at an estimated ratio of 3:1. Below is an illustration of how one of the sections operate.

The Burnaby Waste-to-Energy Facility: a waste management system that ensures efficiency and preservation of the environment.

Waste Disposal Process Flow:

- Trucks draw wastes from the curb and municipal transfer stations to the plant facility. The wastes are weighed and unloaded into a waste bunker. Bunkers have a waste capacity of 4,000 tonnes.

- The waste bunker is secured within the plant facility. Air is sucked from the bunkers to aid in burning. No odour is allowed to escape. Two cranes situated at the top mix the waste, draws the mixed waste, and deposits them into chutes.

- Waste travels down to the bottom of the chute and reaches a grate where incineration takes place at 1000 degrees Celsius. This process leaves bottom ash - residues that were not completely burned. Bottom ash is deposited into an ash discharger and transported to an ash bunker.

- Incineration generates heat and gas and these are diverted into the boiler region. Once in this area, they start to heat up water-filled tubes. In the process of heating, the water inside the tubes becomes steam in a procedure where gas is cooled. These gases are transported to the flue glass cleaning system.

- When steam is produced via the WTEF, it is transported to turbo generator. The generator produces electricity from the steam and is eventually sold to BC Hydro electrical grid.

- Heat residues are recovered by the Heat Recovery Economizer which brings down the gas’ temperature. The partially cooled gas is then made ready for flue gas cleaning.

- Carbon and lime injection reactor traps acid gases and mercury if any.

- Gas is filtered by bags made of cloth material to eradicate any acids, metals and matter.

- Cleaned gas is emitted via a stack that is 60 meters tall, comparable to the height of the B.C. Place Stadium.

Some of the steam generated by WTEF is purchased by a paper mill which manufactures cardboard from recycled paper products. Fly ash coming from the minute particles of burned waste that flies into the air is trapped by the flue glass cleaning system. After treatment, fly ash is discarded as regular municipal sold waste. Approximately 80 trucks of waste are dumped into the bunker daily on all days of the week!

Around 70 percent of the refuse that goes into the facility is composed of bottom ash. Bottom ash contains ferrous metals which are culled from the ash through magnets. These metals are then purchased by a company that recycles them into reinforced steel. After the bottom ash is clear of ferrous metals, it is used on landfill sites as well as building material for roads.

- Published: 2010-11-24T11:51:15-08:00

- Author: Laura Schmidt, Dumpster Rentals Customer Supp